Modern manufacturing is a strange beast. The tools to create physical products have been around for millennia, but the power of computers and data storage only recently caught up with them, making it possible to produce almost any product imaginable in a matter of hours or even minutes.

That’s why we’ve compiled this list of technologies that have changed the face of manufacturing. From 3D printing to precision machining, these innovations are changing how goods are made and are shaping the future.

Conveyor belts

By the early 20th century, many plants were applying the most advanced techniques of plate-glass production to mechanical fabrication; for example, wheels could be built and bolted together with minimum waste. The belt-driven production method was first tested in a Ford vehicle assembly plant in 1913, but it took until the 1940s before it was widely deployed. The speed and efficiency at which these conveyors moved parts was a huge advantage over human workers.

Where they still operate: at fluent conveyors, you can see a wide range of conveyor belts that are installed in many different configurations and for a variety of processes. You might use them if you want to bring a product or process to a production line at high speed and want each step in the process supervised by someone who can see the entire line at once; or if you’re making an article with many different steps, such as in sports equipment manufacturing.

3D printing

In the late 1990s, 3D printers were regarded as major technological breakthroughs for manufacturing. A group of MIT graduates developed a method for expanding gels to make three-dimensional objects, but commercial devices remained expensive and difficult to operate. Now, more than a decade later, 3D printers are finally approaching the price point where they can be used for mass production.

Where they still operate: while there’s still some debate about what makes 3D-printed objects stronger than their traditionally manufactured counterparts, that may not be a concern for some companies. For example, makers of exercise equipment or orthodontic products might find 3D printing especially useful since the size and shape of these items can be customized to any patient without requiring years of development. In addition to its use in manufacturing, 3D printing could also have a big impact on our daily lives soon.

Steam power

Early steam engines were used to pump water and grind grain in the late 18th century, but it wasn’t until the turn of the 20th century that they started to find a place in industrial manufacturing. Today, steam-powered machinery is still used in power production and other tasks where it excels at generating energy.

Where they still operate: you might find steam turbines in power plants or older machines inside abandoned factory buildings.

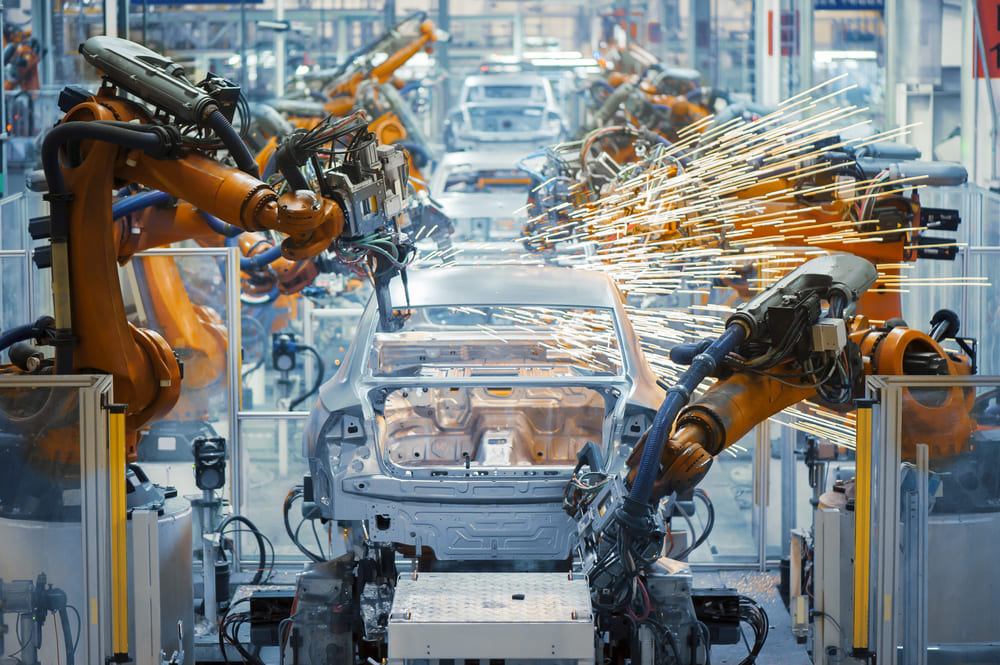

Artificial intelligence (AI)

The idea of robots and artificial intelligence has been around since the dawn of storytelling. It’s not until recently, however, that AI has achieved the level of sophistication needed to make a difference in manufacturing.

Where they still operate: AI is used in many different ways in manufacturing today. For example, voice-activated robots can be controlled by a worker at one facility or an employee away from the plant—and sometimes even by a customer on the phone.

Modern manufacturing is a strange beast. New technologies are developing more rapidly; however, you can see that some of the older technologies are now working in partnership with new ones to improve manufacturing processes.